As indispensable micronutrients critical to human health, vitamins demand precise and efficient extraction methodologies to meet the rigorous requirements of the food, pharmaceutical, and nutraceutical industries. This work provides a methodical review of isolation strategies for both aqueous-soluble (e.g., ascorbic acid, B-complex vitamins) and lipid-soluble (e.g., vitamins A, D, E, K) micronutrients, encompassing conventional approaches and innovative advancements. Through comparative analysis of real-world applications, we assess their contextual applicability, merits, and limitations, offering actionable insights for technology selection across diverse industrial paradigms.

Classification and Isolation Challenges of Vitamins

Vitamins are categorized into two primary groups based on their solubility properties:

Water-Soluble Vitamins

- Representatives: Ascorbic acid (vitamin C), B-complex vitamins (B₁, B₂, B₆, B₁₂).

- Physicochemical Properties: High hydrophilicity, susceptibility to thermal degradation (e.g., vitamin C oxidation at elevated temperatures).

- Extraction Challenges: Oxidative degradation during processing. Low recovery rates due to polar solvent limitations.

Lipid-Soluble Vitamins

- Representatives: Retinoids (vitamin A), calciferols (vitamin D), tocopherols (vitamin E), phylloquinones (vitamin K).

- Physicochemical Properties: Solubility in nonpolar solvents, photolability, and oxygen sensitivity.

- Extraction Challenges: Isomerization risks under heat or light exposure. Co-extraction of lipid matrices (e.g., triglycerides, sterols) complicating purification.

The following is an introduction to the common vitamin extraction methods, their principles and applications, covering different types of vitamins (fat-soluble, water-soluble) and sample substrates (food, biological samples, etc.).

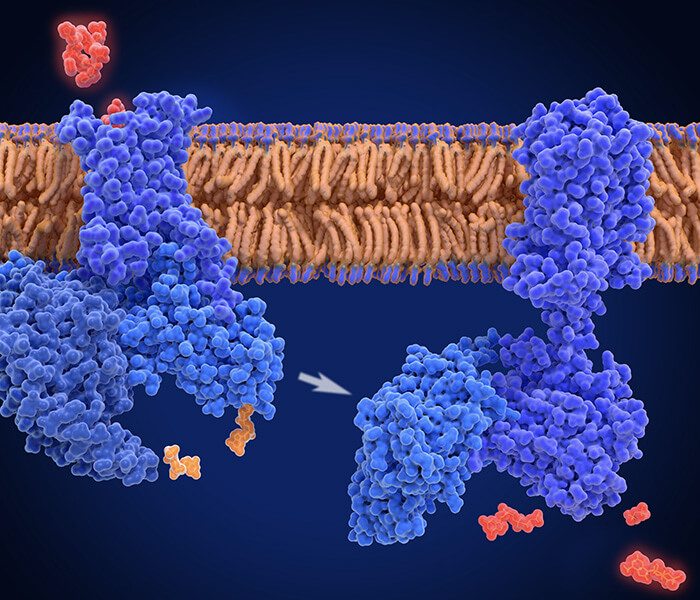

Sample pretreatment scheme for vitamins in different matrices (Li X et al., 2025).

Sample pretreatment scheme for vitamins in different matrices (Li X et al., 2025).

Select Service

Organic Solvent Extraction Method

1.1 Fundamental Principles

- Principle of Polarity Compatibility

Based on the "like dissolves like" concept, solvent selection must align with the target vitamin's polarity:- Fat-soluble vitamins (A/D/E/K): Characterized by extended alkyl chains or aromatic structures, these exhibit minimal polarity. Nonpolar solvents (e.g., n-hexane, diethyl ether) are optimal, leveraging hydrophobic affinity for extraction.

- Water-soluble vitamins (B-complex/C): Contain hydrophilic moieties (e.g., hydroxyl, amino groups). Polar solvents (methanol, ethanol) or pH-adjusted solutions (e.g., 0.1% HCl for acid-stable vitamin C) enhance solubility.

- Partition Coefficient (K): Extraction efficiency depends on the compound's distribution between the solvent and sample matrix. Adjusting solvent ratios (e.g., n-hexane/acetone blends) optimizes this coefficient.

1.2 Operational Protocols and Parameter Optimization

(1) Solvent Systems and Ratios

| Vitamin Type | Recommended Solvent | Mixing Ratio | Application |

|---|---|---|---|

| A, E | n-Hexane-Acetone | 8:2–9:1 | Animal tissues, plant oils |

| D | Chloroform-Methanol | 2:1 | Fortified dairy, cod liver oil |

| C | 1% Metaphosphate-Methanol | 7:3 | Fruits, juices |

| B-complex | Phosphate buffer (pH 6.8) | Pure aqueous | Cereals, meats |

(2) Critical Procedural Parameters

- Homogenization: Achieve particle size <0.5 mm using a high-speed homogenizer (10,000 rpm, 3 min).

- Agitation/Centrifugation:

- Agitation: 20–30 min (fat-soluble); 10–15 min (water-soluble, minimizing oxidation).

- Centrifugation: 10,000 ×g, 15 min at 4°C (preserves thermo-sensitive vitamins).

- Concentration:

- Rotary evaporation (40°C, <100 mbar) followed by residue reconstitution in 1 mL methanol.

- Nitrogen evaporation for trace analysis (prevents thermal degradation).

(3) Impurity Removal

- Fat-soluble extracts: Wash with 10% NaCl to eliminate hydrophilic contaminants.

- Water-soluble extracts: Purify via C18 solid-phase extraction columns.

1.3 Comparative Analysis of Strengths and Limitations

| Advantages | Challenges | Mitigation Strategies |

|---|---|---|

| Broad applicability across solid/liquid matrices | Potential solvent residues | Use low-toxicity alternatives (e.g., cyclohexane) or nitrogen purging |

| Cost-effective (minimal specialized equipment) | Emulsion formation | Add demulsifiers (isopropanol) or pre-centrifugation freezing |

| Scalable for industrial use | Suboptimal recovery of water-soluble vitamins | Multi-stage extraction (3×20 mL solvent) with supernatant pooling |

Ultrasonic-Assisted Extraction (UAE)

2.1 Core Principles and Mechanisms

- Cavitation Dynamics: High-frequency sound waves (20–100 kHz) induce pressure oscillations in solvents, generating microscopic cavitation bubbles. Upon collapse, these bubbles transiently release extreme localized conditions (~5000 K, 1000 bar), disrupting cellular structures to liberate intracellular vitamins.

- Ancillary Mechanisms

- Mechanical Agitation: Amplifies solvent-sample interfacial contact, accelerating mass transfer.

- Controlled Thermal Influence: Mild temperature elevation (<50°C) lowers solvent viscosity but requires precise regulation to prevent oxidative degradation of heat-labile vitamins (e.g., C, B1).

2.2 Critical Parameters and Optimization Approaches

(1) Instrumentation Parameters

| Parameter | Optimal Range | Functional Impact |

|---|---|---|

| Frequency | 20–40 kHz | Lower frequencies enhance penetration in fibrous matrices (e.g., grain husks). |

| Power Intensity | 100–500 W | Adjust proportionally to sample mass (e.g., 200 W for 5 g). Excessive power induces thermal hotspots. |

| Pulsation Mode | 5 s on / 2 s off | Mitigates heat accumulation, preserving thermo-sensitive analytes. |

| Temperature Control | Water bath (25–30°C) | Stabilizes extraction environment, critical for heat-prone vitamins (e.g., vitamin C). |

(2) Solvent Design

| Target Vitamin | Solvent System | Rationale |

|---|---|---|

| C | 1% Metaphosphate + 0.1% EDTA | Antioxidant protection and metal ion chelation. |

| B-Complex | 50% Ethanol + 0.1M HCl | Acidic ethanol solubilizes B1/B2 while inhibiting enzymatic degradation. |

| A, E | n-Hexane-Isopropanol (9:1) | Enhances solvent penetration into lipid-rich matrices. |

2.3 Operational Workflow and Innovations

(1) Standard Protocol

- Sample Preparation:

- Solids: Lyophilize, pulverize to 60-mesh, and homogenize.

- Liquids: Direct solvent blending (e.g., vitamin C extraction from juices).

- Extraction Phase:

- Probe Sonication: Ideal for small volumes (<50 mL), enabling direct immersion.

- Bath Sonication: Suitable for light-sensitive or bulk extractions (e.g., vitamin A).

- Post-Processing:

- Centrifuge, filter (0.22 μm nylon), and concentrate via freeze-drying (water-soluble) or nitrogen evaporation (fat-soluble).

(2) Integrated Methodologies

- Enzymatic Pretreatment + UAE: Cellulase pretreatment (50 U/g) before UAE boosts vitamin B1 yield by 40%.

- RSM-Optimized UAE: Box-Behnken design refines parameters (e.g., 30 min sonication, 250 W, 20:1 liquid-solid ratio) for maximal vitamin C recovery.

Diagram of an ultrasonic bath (Bhadange YA et al., 2024).

Diagram of an ultrasonic bath (Bhadange YA et al., 2024).

2.4 Comparative Evaluation and Enhancements

| Strengths | Limitations | Mitigation Strategies |

|---|---|---|

| Rapid processing (50–70% time reduction) | Thermal degradation risks | Pulse mode with external cooling (e.g., chilled water circulation). |

| Reduced solvent usage (30–50% savings) | Probe contamination | Titanium probes + post-use ethanol rinsing. |

| Versatile matrix compatibility | Noise pollution | Soundproof enclosures; operator ear protection. |

Solid Phase Extraction (SPE)

3.1 Principles and Adsorbent Selection

(1) Retention Mechanisms

The interaction between analytes and adsorbents governs SPE efficiency, with elution conditions tailored to vitamin polarity:

- Fat-soluble vitamins (A/D/E/K): Retained via nonpolar affinity on C18/C8 or silica columns, requiring elevated organic solvent concentrations (e.g., methanol, acetonitrile) for elution.

- Neutral water-soluble vitamins (B-complex/C): Captured through dual hydrophilic-hydrophobic interactions on HLB columns, eluted with low-ionic aqueous-methanol blends.

- Ionic water-soluble vitamins (e.g., B12): Adsorbed via electrostatic forces on strong cation-exchange (SCX) resins, necessitating high-pH buffers (e.g., ammonia-methanol).

- Multi-vitamin mixtures: Separated using mixed-mode sorbents (e.g., MCX) combining hydrophobic and ionic interactions, followed by gradient elution.

(2) Adsorbent Performance Evaluation

| Adsorbent | Target Vitamins | Loading (mg/g) | pH Range | Key Attributes |

|---|---|---|---|---|

| C18 | A, D, E, K | 5–10 | 2–9 | Superior hydrophobicity for lipid-rich matrices |

| HLB | B-complex, C | 15–20 | 1–14 | Broad compatibility with organic/aqueous phases |

| SCX | B12, folate | 3–8 | 2–12 | Selective cation binding under acidic conditions |

| Graphitized Carbon | Pigmented samples | 2–5 | 1–13 | Efficient pigment/sterol removal |

3.2 Operational Optimization

Standard Protocol

- Column Conditioning:

- C18: Sequential 5 mL methanol and water to enhance hydrophobicity.

- SCX: Pre-treated with 0.1M HCl, water, and methanol for functional group activation.

- Sample Loading:

- Flow rate: 1–2 mL/min to balance penetration risk and processing time.

- Solvent compatibility: Ensure sample polarity aligns with conditioning solvent (e.g., ≤5% organic content for C18).

- Impurity Elution:

- Fat-soluble: 5% methanol in water removes hydrophilic contaminants.

- Water-soluble: 2% formic acid eliminates neutral interferents.

- Target Recovery:

- Eluent volume: 2–3× column bed volume (e.g., 3 mL for 1 g adsorbent).

- Fractional collection: Prioritize initial 0.5 mL for concentrated analytes.

The extraction process of tea samples (Fan B et al., 2018).

The extraction process of tea samples (Fan B et al., 2018).

3.3 Strengths, Limitations, and Solutions

| Advantages | Challenges | Enhancements |

|---|---|---|

| Exceptional purification (>90% matrix removal) | Cost-intensive adsorbents | Miniaturized columns (30 mg) or regenerated sorbents (3× reuse post-methanol/acetone wash) |

| Minimal solvent use (<10 mL per run) | Manual complexity | Automated 96-well SPE platforms |

| Customizable for complex matrices | Ion suppression (MS interference) | Volatile eluents or online desalting |

Microwave-Assisted Extraction (MAE)

4.1 Core Principles and Mechanisms

Dielectric Heating Dynamics

Microwaves (typically 2450 MHz) induce thermal energy through molecular dipole rotation and ionic conduction in polar solvents (e.g., water, methanol), enabling rapid cell wall disruption via selective heating.

- Fat-soluble vitamins (A/D/E): Polar co-solvents (e.g., ethanol) enhance dielectric properties, improving microwave energy absorption.

- Water-soluble vitamins (B-complex/C): Direct extraction using aqueous or acidified solvents (e.g., 1% oxalic acid).

Non-Thermal Effects

Electromagnetic interactions may alter hydrogen bonding and molecular diffusion rates, accelerating vitamin release (e.g., 20% efficiency boost for vitamin B1).

Diagram of microwave assisted extraction (Bhadange YA et al., 2024).

Diagram of microwave assisted extraction (Bhadange YA et al., 2024).

4.2 Critical Parameters and Optimization

(1) Instrumentation Settings

| Parameter | Optimal Range | Functional Impact |

|---|---|---|

| Power Output | 300–800 W | Higher settings (600+ W) improve fiber-rich matrix penetration (e.g., grains) but risk thermal degradation. |

| Irradiation Duration | 5–20 min | Prolonged exposure (>10 min) reduces yields (e.g., 15% vitamin C loss). |

| Temperature Control | Feedback-cooled (<60°C) | Prevents localized overheating via forced air/water circulation. |

| Solvent-to-Sample | 1:10–1:20 | Insufficient volume compromises extraction; excess impedes microwave efficiency. |

(2) Solvent System Design

| Vitamin Type | Solvent Blend | Rationale |

|---|---|---|

| A, D, E | n-Hexane-Ethanol (7:3) | Ethanol boosts microwave coupling; n-hexane dissolves lipophilic analytes. |

| C | 1% Oxalic Acid | Acidic medium stabilizes ascorbic acid; water acts as microwave absorber. |

| B-Complex | Methanol-Water (5:5) + 0.1M HCl | Methanol adjusts polarity; HCl inhibits B12 degradation. |

4.3 Operational Workflow and Innovations

(1) Standard Protocol

- Sample Preparation:

- Solids: Lyophilize, pulverize to 60-mesh, and homogenize with solvent.

- Liquids: Add solvent directly (e.g., diatomaceous earth for aqueous stabilization).

- Extraction Phase:

- Use PTFE vessels under pulsed irradiation (30 s on/15 s off) to minimize thermal stress.

- Post-Processing:

- Rapid cooling (ice bath/module), centrifugation (10,000 ×g, 10 min), and 0.45 μm filtration.

- Concentrate via nitrogen evaporation for trace analysis.

(2) Advanced Hybrid Techniques

- Enzymatic Pre-Treatment + MAE: Cellulase digestion (50 U/g, 30 min) prior to MAE reduces vitamin B1 extraction time to 8 min.

- Real-Time Monitoring Integration: Fiber-optic sensors and pressure feedback dynamically adjust power (e.g., auto-throttling at >10 bar).

4.4 Comparative Evaluation and Solutions

| Strengths | Limitations | Enhancements |

|---|---|---|

| Ultra-rapid processing (70–90% faster) | High equipment costs | Modular components to lower upkeep expenses (e.g., replaceable magnetrons). |

| Low solvent demand (20–30% of Soxhlet) | Temperature instability | Infrared sensors with adaptive power modulation. |

| Selective heating preserves labile analytes | Safety hazards | Explosion-resistant vessels with pressure-release valves. |

Enzymatic Hydrolysis

5.1 Core Principles and Mechanisms

(1) Enzyme-Substrate Specificity

Enzymes target specific biomolecules in the sample matrix to liberate bound vitamins:

| Enzyme | Substrate | Released Vitamin | Application |

|---|---|---|---|

| α-Amylase | Starch | B1 (bound form) | Cereals (rice, wheat) |

| Cellulase | Plant cell walls | C, carotenoids | Fruits/vegetables (spinach, carrots) |

| Protease | Proteins | B12 (protein-bound) | Animal tissues (liver, fish) |

| Pectinase | Pectin | E (cell wall-bound) | Plant oils (soybean, sunflower) |

(2) Synergistic Systems

Multi-enzyme blends (e.g., cellulase-pectinase) enhance cell wall degradation, boosting vitamin liberation (e.g., 40% higher folate yield in spinach).

5.2 Operational Workflow and Parameter Optimization

(1) Standard Protocol

- Sample Preparation:

- Solids: Pulverize to <0.5 mm for increased enzyme accessibility.

- Liquids: Adjust pH to enzyme-specific optima (e.g., pH 6.0 for amylase).

- Hydrolysis Phase:

- Enzyme dosage: 1–5% (w/w), tailored to matrix complexity (e.g., 2% amylase for grains).

- Incubation: 37–50°C with agitation (100 rpm, 30–120 min).

- Enzyme Deactivation:

- Thermal: 80°C, 10 min (heat-stable vitamins like E).

- Chemical: Acid/alkali treatment (e.g., pH 2.0 HCl for heat-labile vitamins like C).

- Post-Hydrolysis Processing:

- Centrifuge (10,000 ×g, 15 min) → 0.45 μm filtration → SPE purification (trace analysis).

(2) Critical Parameter Optimization

| Parameter | Optimal Range | Functional Impact |

|---|---|---|

| Temperature | Enzyme optimum ±5°C | Excess heat denatures enzymes; low temps slow kinetics. |

| pH | Enzyme optimum ±0.5 | Deviations reduce activity (e.g., pepsin at pH 2.0). |

| Enzyme:Substrate Ratio | 1:50–1:100 (w/w) | High ratios raise costs; low ratios yield incomplete hydrolysis. |

| Duration | 30–120 min | Prolonged incubation risks oxidation (e.g., vitamin C loss). |

5.3 Comparative Evaluation and Solutions

| Strengths | Challenges | Enhancements |

|---|---|---|

| Targeted matrix decomposition | High enzyme costs | Immobilized enzymes (e.g., magnetic nanoparticle-bound) for 5–10 reuse cycles. |

| Mild extraction conditions | Time-intensive | Ultrasound integration halves processing time. |

| Eco-friendly (low solvent use) | Enzyme instability | Stabilizers (glycerol, trehalose) extend shelf life. |

Supercritical Fluid Extraction (SFE)

6.1 Fundamental Principles and Fluid Properties

(1) Supercritical CO₂ Characteristics

- Critical Parameters:

- Critical temperature (Tc): 31.1°C

- Critical pressure (Pc): 73.8 bar

- Supercritical State (> Tc and Pc): Combines gas-like diffusivity with liquid-like solvation capacity.

- Solubility Dynamics:

| Target Compound | Optimal Pressure Range | Interaction Mechanism |

|---|---|---|

| Vitamin E | 250–350 bar | CO₂ affinity for hydrophobic alkyl chains in tocopherols. |

| Vitamin A | 300–400 bar | Enhanced retinol ester dissolution under elevated pressure. |

| Carotenoids | 350–450 bar | Polar ketone group solvation at high pressure. |

(2) Modifier Optimization

- Polarity Enhancement:

- Entrainers: 1–10% ethanol, methanol, or water improves polar analyte extraction (e.g., vitamin D₃ solubility triples with 5% ethanol).

6.2 System Configuration and Operational Refinement

(1) Key Components and Parameters

| Component | Function | Operational Specifications |

|---|---|---|

| Extraction Vessel | High-pressure processing | Capacity: 50 mL (lab) to 50 L (industrial); withstands ≤600 bar. |

| CO₂ Pump | Precise fluid delivery | Dual-plunger design (0.1 bar accuracy) eliminates pulsation. |

| Separation Chamber | Phase separation | Multi-stage depressurization (5–50 bar) enhances purity (e.g., lipid removal followed by vitamin collection). |

| Thermal Regulation | Temperature stability | Jacketed water circulation (±0.5°C accuracy). |

(2) Operational Protocol

- Sample Preparation:

- Solids: Granulate to 40–60 mesh; bulk density 0.3–0.5 g/cm³ to prevent channeling.

- Liquids: Adsorb onto inert substrates (e.g., diatomaceous earth).

- Dynamic Extraction:

- CO₂ flow rate: 10–40 g/min (lab) or 500–2000 kg/h (industrial).

- Duration: 30–120 min (scalable to sample mass).

- Fraction Collection:

- Pressure-Driven: Reduce to 50 bar to precipitate vitamin E.

- Thermal-Driven: Increase to 60°C to lower CO₂ density, releasing target analytes.

Diagram of supercritical fluid extraction (Bhadange YA et al., 2024).

Diagram of supercritical fluid extraction (Bhadange YA et al., 2024).

6.3 Strengths, Limitations, and Innovations

| Advantages | Challenges | Solutions |

|---|---|---|

| Solvent-free output (FDA/EFSA compliant) | High capital investment (>$5M for industrial systems) | Offset by long-term savings via eliminated solvent recovery. |

| Low-temperature processing (preserves thermolabile vitamins) | Limited to lipophilic targets | Experimental CO₂-ionic liquid blends for polar analytes. |

| CO₂ recyclability (>95% recovery, eco-friendly) | Mass transfer inefficiencies | Ultrasound integration boosts efficiency by 30%. |

QuEChERS Method

7.1 Core Principles and Mechanisms

(1) Key Procedural Functions

- Solvent Extraction (Acetonitrile): Acetonitrile exhibits dual solubility, enabling concurrent extraction of hydrophilic (e.g., B-complex, C) and lipophilic vitamins (e.g., E, carotenoids). Adjusting solvent polarity with water (e.g., 4:1 acetonitrile:water ratio) enhances cellular disruption, liberating bound analytes.

- Salting-Out Phase Separation:

- MgSO₄: Induces dehydration and exothermic reactions, accelerating solvent-matrix separation.

- NaCl: Reduces vitamin solubility in acetonitrile via salt-induced phase partitioning, minimizing co-extracted impurities.

- Adsorbent Purification:

| Adsorbent | Function | Target Vitamins | Application |

|---|---|---|---|

| PSA | Removes acids, sugars, pigments | B, C | Fruits, vegetables |

| C18 | Adsorbs lipids, sterols | Fat-soluble (D, E) | Dairy products |

| GCB | Eliminates chlorophyll, polyphenols | A, E | Leafy greens |

| Z-SEP+ | Broad-spectrum impurity removal | Multi-vitamin analysis | Complex matrices |

7.2 Operational Optimization and Parameters

(1) Standard Protocol

- Sample Preparation:

- Solids: Cryogenic grinding (<1 mm particle size; e.g., liquid nitrogen treatment).

- Liquids: Direct aliquot (1–5 mL) into extraction tubes.

- Extraction Phase:

- Solvent: Acetonitrile-water (4:1, 1% formic acid) stabilizes labile vitamins (e.g., B₁).

- Salting agents: 4 g MgSO₄ + 1 g NaCl for rapid phase separation.

- Centrifugation:

- Conditions: 10,000 ×g, 5 min at 4°C to mitigate thermal degradation (e.g., vitamin C loss).

- Purification:

- Adsorbent mix: 150 mg PSA + 50 mg C18 + 10 mg GCB for balanced impurity removal.

- Vortexing: 2 min for optimal adsorbent-sample interaction.

- Filtration: 0.22 μm nylon filtration prior to HPLC or LC-MS/MS analysis.

(2) Multi-Vitamin Analysis Optimization

| Vitamin Class | Extraction Strategy | Detection Method |

|---|---|---|

| Water-soluble (B, C) | 0.1% EDTA to inhibit oxidation | HPLC-UV (λ = 245 nm for C) |

| Fat-soluble (A, E) | 5% isopropanol for enhanced solubility | LC-MS/MS (positive ion mode) |

| Acid/Base-sensitive (B₁₂) | pH 4.5 (formic acid) stabilization | Fluorescence detection (post-derivatization) |

7.3 Comparative Evaluation and Solutions

| Advantages | Challenges | Innovative Solutions |

|---|---|---|

| High throughput (batch processing) | Complex adsorbent optimization | Experimental design (e.g., Plackett-Burman) for optimal combinations |

| Rapid and cost-effective (<15 min/sample) | Matrix effects in MS analysis | Isotope-labeled internal standards (e.g., ¹³C-vitamin C) |

| Versatility (dual extraction of polar/nonpolar vitamins) | Acetonitrile toxicity | Alternative solvents (e.g., propionitrile, ethyl acetate blends) |

People Also Ask

What are the common methods for quantifying vitamins in biological samples?

Common methods of vitamin analysis include chromatography, spectroscopy, and immunoassays. Each method offers varying levels of accuracy, cost, and convenience. These techniques help in precisely measuring vitamin levels ensuring reliable results.

Which method is used for assay of vitamins?

Vitamin detection methods: Fat-soluble vitamins (A, D, E, K) are usually analyzed by LC-MS/M to achieve high-sensitivity multicomponent analysis; Water-soluble vitamins (B and C) are mostly determined by HPLC combined with ultraviolet/fluorescence detection or LC-MS, which is suitable for trace quantification in complex matrices.

If you want to know about the methods of microbial analysis, please click "Analytical Methodologies for Fat-Soluble Vitamin Determination".

If you want to know about the methods of microbial analysis, please click "Review on Analytical Methods of Water-Soluble Vitamins".

References

- Li X, Lv H, Luo W, Yang W, Kong L, Zhu Q, Zeng L. "Recent advances in detection techniques for vitamin analysis: A comprehensive review." Food Chem X. 2025 Jan 31;26:102226. doi: 10.1016/j.fochx.2025.102226

- Zhang Y, Zhou WE, Yan JQ, Liu M, Zhou Y, Shen X, Ma YL, Feng XS, Yang J, Li GH. "A Review of the Extraction and Determination Methods of Thirteen Essential Vitamins to the Human Body: An Update from 2010." Molecules. 2018 Jun 19;23(6):1484. doi: 10.3390/molecules23061484

- Fan B, You J, Suo Y, Qian C. "A novel and sensitive method for determining vitamin B3 and B7 by pre-column derivatization and high-performance liquid chromatography method with fluorescence detection." PLoS One. 2018 Jun 6;13(6):e0198102. doi: 10.1371/journal.pone.0198102

- Bhadange YA, Carpenter J, Saharan VK. "A Comprehensive Review on Advanced Extraction Techniques for Retrieving Bioactive Components from Natural Sources." ACS Omega. 2024 Jul 8;9(29):31274-31297. doi: 10.1021/acsomega.4c02718

- Herzyk F, Piłakowska-Pietras D, Korzeniowska M. "Supercritical Extraction Techniques for Obtaining Biologically Active Substances from a Variety of Plant Byproducts." Foods. 2024 May 30;13(11):1713. doi: 10.3390/foods13111713