Sugar Alcohols Analysis Service

Struggling with co-eluting polyols, trace-level detection, or unreliable quant data?

Creative Proteomics delivers validated, matrix-specific sugar alcohol profiling for research, formulation, and production.

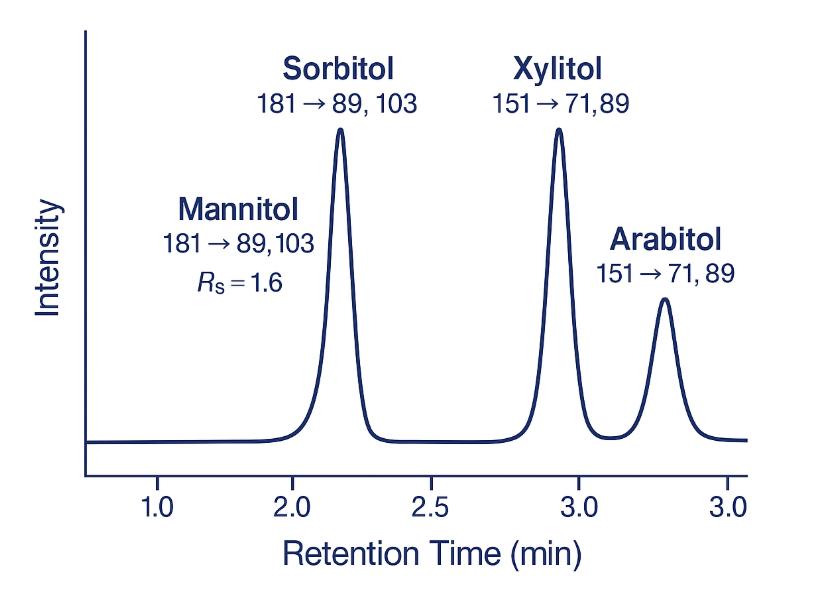

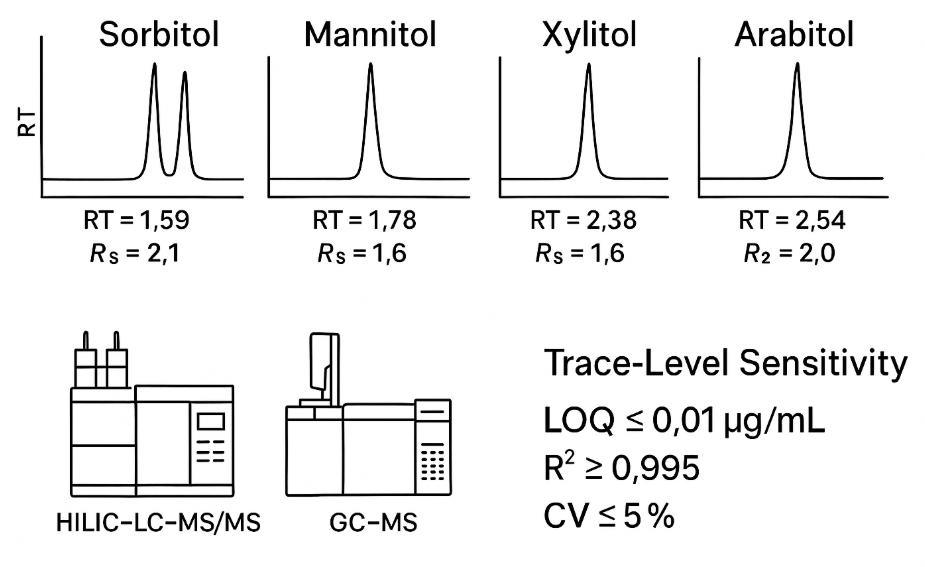

- Resolve isomers like sorbitol vs mannitol with chromatographic clarity

- Quantify polyols down to ng/mL levels across complex food, bio, or chemical matrices

- Cross-verified by LC–MS/MS, GC–MS/MS, and HPAEC–PAD for audit-ready confidence

- Receive full data package: raw files, QC plots, calibration curves, and interpretation

Submit Your Request Now

×

What You Will Receive

- Raw Data: Instrument files (.raw / .wiff) and converted formats (.mzML)

- Quant Tables: Absolute concentrations with LOQ, R², and CV metrics

- Chromatograms: Annotated MRM/XIC plots with RT and isomer separation

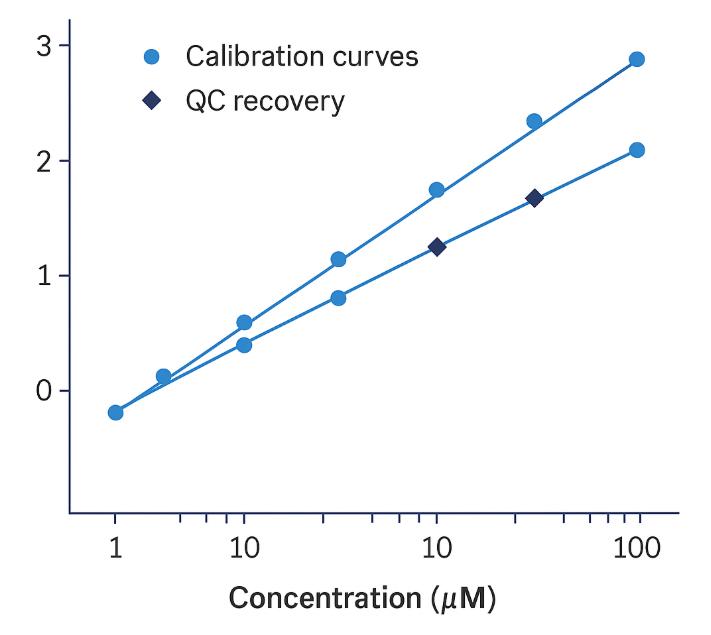

- Calibration & QC: Standard curves with recovery and linearity stats

- Summary Report: Method overview and brief interpretation

- Optional Validation: GC–MS or PAD-based orthogonal confirmation

- What We Provide

- Advantages

- Technology Platform

- Sample Requirement

- Demo

- FAQs

What Are Sugar Alcohols?

Sugar alcohols (polyols) are reduced monosaccharides that contain multiple hydroxyl groups, making them highly polar and often isomeric. Common representatives such as erythritol, xylitol, sorbitol, mannitol, and inositols are widely used in biochemical research, fermentation systems, and formulation development.

Due to their similar structures and low molecular weights, sugar alcohols are notoriously difficult to separate and quantify using standard methods. Their high hydrophilicity leads to poor retention in reversed-phase LC, and isomeric forms often co-elute or share identical mass transitions. Reliable analysis requires platform-specific separation strategies, tailored ionization conditions, and validated calibration schemes.

Creative Proteomics applies optimized HILIC–MS/MS and derivatized GC–MS/MS workflows to resolve these challenges, enabling accurate, isomer-specific quantification across diverse sample types.

What Sugar Alcohols Analysis Can We Offer for Your Research

- Targeted absolute quantification of polyols and cyclitols with stable-isotope internal standards where available.

- Isomer-specific methods for sorbitol/mannitol, arabitol/xylitol/ribitol, and inositol stereoisomers.

- Orthogonal platform confirmation: LC–MS/MS + GC–MS/MS and/or HPAEC–PAD when needed.

- Impurity and residual-solvent-like polyol screening in formulations and excipients (e.g., glycerol, propylene glycol).

- Stability and stress-testing support to evaluate polyol content under storage or processing conditions.

Full List of Detectable Sugar Alcohols and Related Detectables

| Analyte (Common Name) | Synonym/Isomer Notes | Recommended Method(s) | Typical LOQ (µg/mL) | Notes |

|---|---|---|---|---|

| Erythritol | Isomer of threitol | HILIC–LC–MS/MS; HPAEC–PAD | 0.01–0.1 | Fast HILIC RT; confirm by qualifier ion ratio |

| Threitol | – | HILIC–LC–MS/MS | 0.02–0.1 | Baseline vs erythritol under amide HILIC |

| Xylitol | Isomer with arabitol | LC–MS/MS; GC–MS/MS (TMS) | 0.01–0.1 | Shared MRM with isomers; RT critical |

| Arabitol (D/L) | Isomer with xylitol, ribitol | LC–MS/MS; HPAEC–PAD | 0.02–0.1 | Report stereochemistry if standards provided |

| Ribitol (Adonitol) | Isomer set | LC–MS/MS; GC–MS/MS | 0.02–0.1 | Qualifier transitions required |

| Sorbitol (D-glucitol) | Isomer with mannitol | LC–MS/MS; HPAEC–PAD | 0.02–0.2 | Baseline Rs typically ≥1.5 vs mannitol |

| Mannitol | – | LC–MS/MS; HPAEC–PAD | 0.02–0.2 | Robust in food matrices |

| Galactitol (Dulcitol) | – | LC–MS/MS; GC–MS/MS | 0.02–0.2 | Useful in excipient profiling |

| Maltitol | Disaccharide polyol | LC–MS/MS | 0.05–0.5 | HILIC improves peak shape |

| Lactitol | Disaccharide polyol | LC–MS/MS | 0.05–0.5 | Matrix-matched calibration advised |

| Isomalt (GPS/GPM) | Isomeric mixture | LC–MS/MS | 0.05–0.5 | Report sum and components on request |

| myo-Inositol | Cyclitol | LC–MS/MS; HPAEC–PAD | 0.02–0.2 | Distinct from scyllo-inositol |

| scyllo-Inositol | Cyclitol isomer | LC–MS/MS | 0.02–0.2 | Retention-time separation vs myo- |

| D-chiro-Inositol | Cyclitol isomer | LC–MS/MS | 0.02–0.2 | Requires isomer-aware calibration |

| Glycerol | Triol | GC–MS/MS (TMS); LC–MS/MS | 0.01–0.1 | Common interferent in buffers |

| Propylene glycol | Diol | GC–MS/MS | 0.01–0.1 | Screen as related humectant |

| Ethylene glycol | Diol | GC–MS/MS | 0.01–0.1 | Screen as related diol |

| Sorbitan & partial esters | Related excipients | LC–MS/MS | 0.1–1.0 | Method variant; report as needed |

| Residual monosaccharides | Glucose, fructose, sucrose | HPAEC–PAD | 0.05–0.5 | Context for formulation/fermentation |

LOQ ranges are method- and matrix-dependent; tighter values are established during validation on your matrix.

Advantages of Our Sugar Alcohols Analysis Services

- Sensitivity: demonstrated LOQs in the low-ng/mL to sub-µg/mL range (matrix-dependent) with signal-to-noise ≥10 at LOQ.

- Linearity: r² ≥0.995 over ≥3 orders of magnitude with back-calculated accuracy 85–115%.

- Precision & Accuracy: intra-run CV typically ≤5%, inter-run CV ≤10%; spike-recovery 85–115% in representative matrices.

- Selectivity/Resolution: chromatographic resolution Rs ≥1.5 for key isomer pairs (e.g., sorbitol/mannitol) and qualifier/quantifier ion ratios within ±20% of reference.

- Mass Accuracy (when HRAM is used): ≤5 ppm acceptance with isotope pattern fit as secondary criterion.

- Carryover Control: ≤0.05% after high standard; verified with bracketed blanks.

- Robust Retention: RT RSD typically ≤1.0% across sequences with system-suitability standards.

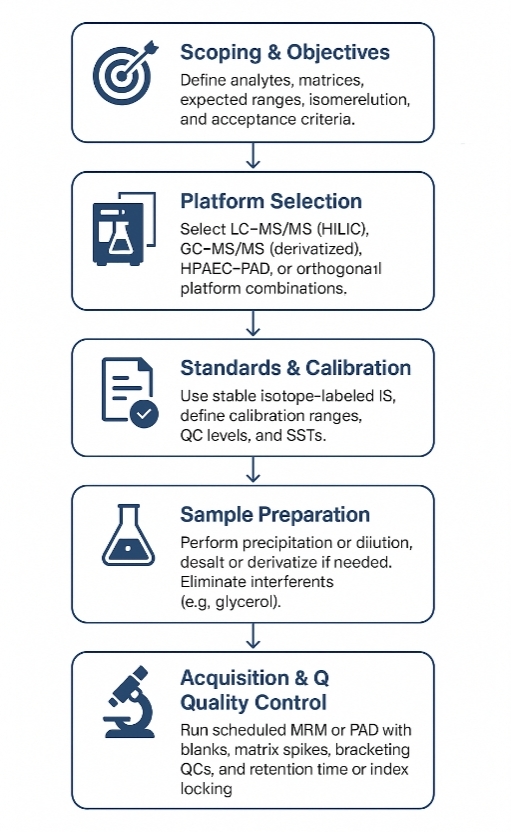

Workflow for Sugar Alcohols Analysis Service

- Scoping Consultation — Define target analytes, matrices, expected ranges, isomer requirements, and acceptance criteria.

- Platform Selection — Choose LC–MS/MS (HILIC), GC–MS/MS (derivatized), HPAEC–PAD, or an orthogonal combination.

- Standards & Calibration Design — Select stable-isotope IS where available; set calibration range, QC levels, and system-suitability tests.

- Sample Preparation — Protein precipitation or dilution; desalting or SPE if required; derivatization for GC routes; strict control of potential interferents (e.g., glycerol in buffers).

- Acquisition & QC — Scheduled MRM or PAD program with blanks, matrix spikes, bracketing QCs, and retention-index or RT lock.

- Quantification & Verification — Weighted regression, back-calculated accuracy review, ion-ratio checks, and orthogonal confirmation where indicated.

- Reporting — Absolute concentrations, uncertainty/QC tables, annotated chromatograms, and a concise interpretation summary aligned to your study goals.

Technology Platform for Sugar Alcohols Analysis Service

LC–MS/MS (Hydrophilic Interaction Chromatography, HILIC)

Application: Primary method for most polyols and cyclitols with high polarity or isomeric overlap.

System: Thermo Vanquish UHPLC + SCIEX 6500+

Column: Amide HILIC (2.1 × 100 mm, 1.7 µm)

Ionization Mode: ESI (negative)

Detection: Scheduled MRM with ≥12 points/peak

Mobile Phase: High-organic (ACN-rich) gradient with volatile buffers (e.g., ammonium acetate)

LOQs: Down to 0.01 µg/mL (compound- and matrix-dependent)

Strengths:

- Isomer resolution (e.g., sorbitol vs mannitol; xylitol vs arabitol)

- Suitable for cyclitols (myo-/scyllo-inositol)

- Compatible with stable-isotope internal standards

GC–MS/MS (Post-Derivatization, TMS)

Application: Secondary method for confirmatory analysis or high-sensitivity detection in simple matrices.

System: Agilent 7890 GC + 7000D Triple Quadrupole

Derivatization: BSTFA + 1% TMCS (trimethylsilylation)

Ionization Mode: EI (electron ionization)

Column: DB-5ms UI (30 m × 0.25 mm × 0.25 µm)

Detection: MRM transitions specific to derivatized polyols

LOQs: Typically 0.01–0.1 µg/mL

Strengths:

- Excellent for low-mass polyols (e.g., erythritol, glycerol)

- High specificity and signal response after derivatization

- Effective for volatile matrix environments

Vanquish UHPLC (Figure from Thermo)

SCIEX Triple Quad™ 6500+ (Figure from Sciex)

7890 GC + 7000D Triple Quadrupole (Figure from Agilent)

Sample Requirements for Sugar Alcohols Analysis Service

| Matrix Category | Minimum Amount | Container | Preservatives/Stabilizers | Notes/Restrictions |

|---|---|---|---|---|

| Fermentation broth / culture supernatant | 1–2 mL | Polypropylene screw-cap tube | Optional: antioxidant-free | Record carbon source and medium composition; avoid glycerol additives if possible |

| Food & beverage (liquid) | 5–10 mL | Sterile plastic bottle or tube | None added | Degas carbonated samples; note sweetener system on COC form |

| Food & plant materials (solid) | 2–5 g | Whirl-Pak®/sealed pouch | None added | Indicate moisture content; we homogenize under controlled conditions |

| Formulations / excipients / cosmetic bases | 1–2 g or mL | Original container or amber PP | None added | List all polyol-containing excipients (e.g., sorbitol solution, PEGs) |

| Cell culture media / perfusates | 1–2 mL | Low-bind PP tube | None added | Filter particulates (0.22 µm) where feasible |

| Environmental/processing water | 50–100 mL | Clean PP bottle | Sodium thiosulfate only if chlorinated | Avoid glycol-containing deicers; note any sanitizers used |

General notes: please avoid buffers or reagents containing glycerol, ethylene/propylene glycol, or sugar alcohols unless these are the targets of quantification; provide a list of potential interferents; indicate desired reporting units and any matrix-matched calibration needs.

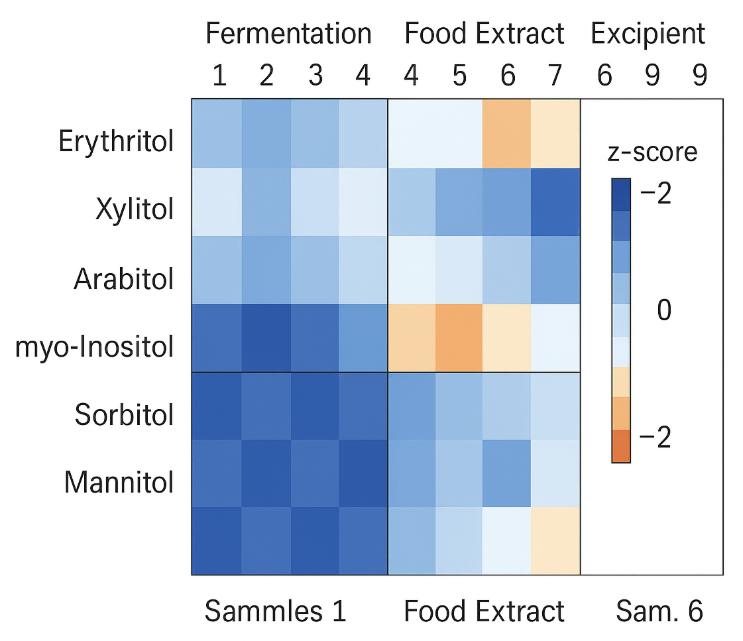

Demo Results

When Do You Need Sugar Alcohols Quantification?

Fermentation Monitoring

Track production and accumulation of polyols as metabolic endpoints or intermediates.

Food Ingredient Validation

Quantify sugar alcohol content for formulation standardization and label accuracy.

Excipient Quality Control

Detect residual polyols (e.g., sorbitol, xylitol) in pharmaceutical or cosmetic matrices.

Bioprocess Optimization

Evaluate carbon flux through polyol pathways to optimize strain performance or yield.

Nutritional Research

Profile sugar alcohol distribution in low-calorie and sugar-replacement product development.

Pathway Mechanism Studies

Use isomer-specific quantification to study flux in aldose reductase or inositol metabolism.

FAQ of Sugar Alcohols Analysis Service

What challenges commonly occur in sugar alcohol quantification?

Isomeric overlap, low ionization efficiency, and matrix interferences are frequent issues. Accurate quantification requires method-specific separation strategies, stable isotope standards, and recovery-validated workflows.

Can sugar alcohol isomers like sorbitol and mannitol be reliably separated?

Yes. When using HILIC–MS/MS with optimized gradient and column selection, baseline resolution (Rs >1.5) can be achieved, allowing precise quantification of structurally similar sugar alcohols.

How do you ensure data reliability across complex sample types?

Each run includes matrix-matched calibrators, internal standards, bracketing QCs, and orthogonal verification (e.g., GC–MS or PAD) to confirm specificity and recoveries across sample classes.

What matrices are compatible with sugar alcohol analysis workflows?

Validated matrices include fermentation broth, food extracts, formulation excipients, cell culture media, and aqueous buffer systems free of interfering polyols (e.g., glycerol or propylene glycol).

Can your methods distinguish between cyclitol isomers such as myo- and scyllo-inositol?

Yes. We employ LC–MS/MS with optimized retention and transition ratios to differentiate inositol stereoisomers, ensuring accurate isomer-specific profiling in biological and industrial samples.

What internal standards are recommended for quantitative accuracy?

Stable isotope-labeled analogs (e.g., sorbitol-13C6, erythritol-d4) are used where available to correct for extraction efficiency and instrument variability, particularly in low-abundance applications.

How do you confirm the identity of each sugar alcohol detected?

Confirmation is based on multiple criteria: retention time match, ion ratio agreement within ±20%, and, when required, cross-platform validation using GC–MS or HPAEC–PAD.

Why do polyol analyses often fail in standard LC–MS labs?

Most labs lack the necessary chromatographic resolution for isomer separation or the ion source optimization required for polyol detection, leading to inaccurate results or false negatives.

Can you accommodate high-throughput screening for sugar alcohols?

Yes. Our platform supports scalable batch analysis with consistent retention reproducibility (RT RSD ≤1%) and automated data processing for large sample sets.

What detection limits can be expected for sugar alcohol analysis?

LOQs vary by compound and matrix, but validated methods typically achieve ng/mL-level sensitivity using scheduled MRM or SIM for derivatized analytes.

Learn about other Q&A about proteomics technology.

Publications

Here are some of the metabolomics-related papers published by our clients:

- A human iPSC-derived hepatocyte screen identifies compounds that inhibit production of Apolipoprotein B. 2023.

- The activity of the aryl hydrocarbon receptor in T cells tunes the gut microenvironment to sustain autoimmunity and neuroinflammation. 2023.

- Lipid droplet-associated lncRNA LIPTER preserves cardiac lipid metabolism. 2023.

- Inflammation primes the kidney for recovery by activating AZIN1 A-to-I editing. 2023.

- Anti-inflammatory activity of black soldier fly oil associated with modulation of TLR signaling: A metabolomic approach. 2023.

- Non-invasive elevation of circulating corticosterone increases the rejection of foreign eggs in female American robins (Turdus migratorius). 2022.

- Untargeted metabolomics reveal sex-specific and non-specific redox-modulating metabolites in kidneys following binge drinking. 2023.

- Nicotine exposure during rodent pregnancy alters the composition of maternal gut microbiota and abundance of maternal and amniotic short chain fatty acids. 2022.

- Sex hormones, sex chromosomes, and microbiota: identification of Akkermansia muciniphila as an estrogen-responsive bacterium. 2023.