What is HILIC-UPLC Analysis?

Hydrophilic Interaction Liquid Chromatography-Ultra Performance Liquid Chromatography (HILIC-UPLC), is an advanced chromatographic technique used for the separation and analysis of hydrophilic compounds based on their polarity and hydrophilicity. It represents a distinctive type of normal-phase chromatography that utilizes a polar stationary phase and a non-polar mobile phase.

Typically, in HILIC-UPLC, the stationary phase comprises polar, hydrophilic materials such as amide, cyano, or diol functional groups, while the mobile phase is typically a water-rich mixture of organic solvents, such as acetonitrile or methanol, which can be modified to change the retention of analytes on the stationary phase.

The HILIC-UPLC methodology is particularly useful for the separation and analysis of polar and hydrophilic compounds, such as peptides, nucleotides, and carbohydrates, which are arduous to separate by other chromatographic techniques. It provides several advantages over traditional normal-phase or reversed-phase chromatography, such as heightened resolution, enhanced sensitivity, and reduced sample preparation.

HILIC-UPLC analysis is a powerful tool widely used in various fields, including pharmaceuticals, metabolomics, and environmental monitoring. It enables the separation, identification, and quantification of hydrophilic compounds in complex mixtures.

1 Preparation

1) Place ultrapure water, methanol, chloroform, and PBS in the refrigerator and allow to cool down to 4 °C.

2) Make a 50 % (v/v) methanol in water solution by mixing equal volumes of ultrapure water and methanol. Make enough to process all of the samples in the batch. Typically, it takes approximately 7 mL of 50 % methanol to process one sample. Store the solution at 4 °C.

3) Label your tubes.

2 Homogenization of Brain Tissue

1) This protocol works with fresh or fresh frozen (unfixed) brain tissue. Place the brain tissue into a 2 mL microfuge tube and add Lysing Matrix D. The quantity of lysing matrix used depends on the starting amount of tissue. Using approximately 5–6 beads per 25 mg of tissue is sufficient to achieve complete homogenization.

2) Add 1 mL of cold ultrapure water to the tube, close the lid and seal tightly with Parafilm.

3) Place the tubes in the FastPrep® -24 Instrument (making sure that the instrument is balanced) and homogenize the tissue using the following settings: Speed 6, Time 40 s. The solution should turn a pale milky color.

4) Transfer the supernatant (leaving the beads behind) into a clean 15 mL tube.

5) Rinse the microfuge tube with 1 mL cold methanol to collect remaining homogenate, vortex briefly and transfer the solution to the same 15 mL tube.

6) Rinse the microfuge tube once more with 0.75 mL cold methanol, vortex briefly and transfer the solution to the same 15 mL tube. Discard the microfuge tube with the beads.

7) Vortex the 15 mL tube, seal it with Parafilm and place it in an ultrasonic water bath.

8) Sonicate for 15 min.

3 Protein Extraction

1) Remove the tube from the water bath, remove the Parafilm, add 3.25 mL of cold chloroform to the tube and vortex well.

2) Tightly seal the lid with Parafilm and sonicate for 15 min.

3) Remove the Parafilm and centrifuge the tube at 4500 × g for 30 min. After centrifugation, separation of the phases should be apparent. The proteins are located at the interface of the aqueous phase (top) and the organic phase (bottom).

4) Carefully remove and discard the aqueous phase using a 1 mL pipette, being careful not to disturb the protein layer.

5) To the remaining organic phase, add an equal volume of cold 50 % methanol solution and vortex well.

6) Repeat steps 2 – 5. Additional cycles of methanol–chloroform extraction help to clean up the proteins.

7) Tightly seal the lid with Parafilm and sonicate for 15 min.

8) Remove the Parafilm and centrifuge the tube at 4500 × g for 30 min.

9) Carefully remove and discard the aqueous phase using a 1 mL pipette, being careful not to disturb the protein layer.

10) To the remaining organic phase, add an equal volume of cold 100 % methanol solution and vortex well. Addition of pure methanol causes precipitation of the proteins.

11) Centrifuge the tube at 4500 × g for 30 min. After centrifugation, a protein pellet should be visible at the bottom of the tube.

12) Carefully remove and discard the supernatant using a 1 mL pipette, being careful not to disturb the protein pellet.

13) Add 0.5 mL cold methanol to the 15 mL tube.

14) Carefully transfer the pellet and methanol solution from the15 mL tube into a 2 mL microfuge tube using a 1 mL pipette.

15) Add a further 0.5 mL cold methanol to the 15 mL tube, rinse the sides of the tube to collect any remaining pieces of the protein pellet and transfer to the same microfuge tube.

16) Centrifuge the tube at 13,000 × g for 15 min.

17) Carefully remove and discard the supernatant using a 1 mL pipette, being careful not to disturb the protein pellet.

18) Add 1 mL cold methanol to the tube and vortex to resuspend the pellet.

19) Centrifuge the tube at approximately 13,000 × g for 15 min.

20) Repeat steps 17 – 19 another two times.

21) Carefully remove and discard the supernatant using a 1 mL pipette, being careful not to disturb the protein pellet.

22) Place the open tubes into a vacuum concentrator and dry for 10 min.

4 Deglycosylation and Cleanup

1) Resuspend the dried protein pellet in 1 mL cold PBS.

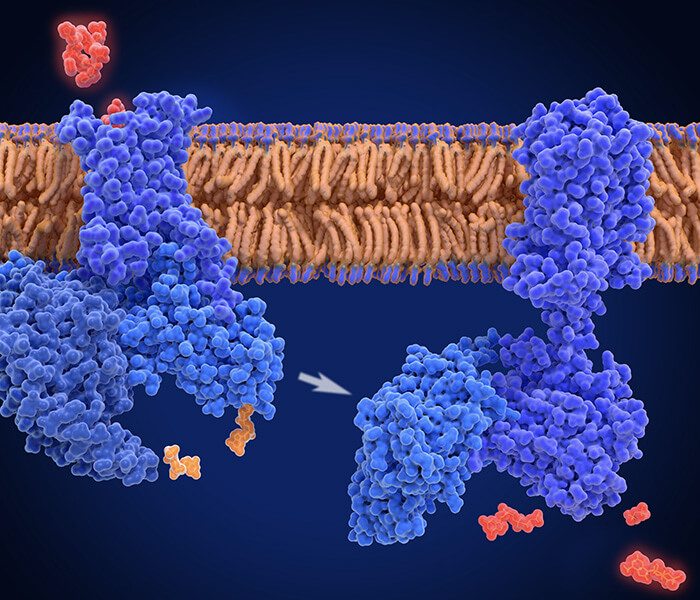

2) Add 150 μL 10 % SDS (final concentration 1.3 % w/v) and 6 μL βME (final concentration 0.5 % v/v). Denaturation of proteins and elimination of disulphide bonds is required for effective deglycosylation by PNGase F.

3) Vortex the solution and incubate in the Thermomixer comfort at 95 °C for 10 min with gentle shaking.

4) Incubate on ice for 5 min.

5) Add 15 μL 10 % NaN3 (final concentration 0.1 % w/v) and 200 μL 10 % IGEPAL CA-630 (final concentration 1.5 % w/v).

6) Add 0.5 μL PNGase F enzyme (5 U), tightly seal the tube with Parafi lm and vortex well.

7) Incubate overnight at 37 °C.

8) The following day repeat steps 6 and 7.

9) The following day prepare the Amicon ® Ultra 2 mL Centrifugal Filter Devices by adding 1 mL of ultrapure water to the filter device and centrifuging for 5 min at 2450 × g.

10) Discard the flow-through, add a further 1 mL of ultrapure water and centrifuge once more for 5 min at 2450 × g.

11) Discard the flow- through and transfer the entire volume of the deglycosylation reaction from the microfuge tube to the filter device. Do not discard the microfuge tube.

12) Centrifuge for 20 min at 4000 × g. Do not discard the flow-through; this contains the free N -glycans.

13) Rinse the microfuge tube in which the deglycosylation reaction took place with 500 μL ultrapure water to collect remaining traces of the reaction mixture and transfer the solution to the filter device.

14) Centrifuge for 10 min at 4000 × g. Do not discard the flowthrough; this contains the free N -glycans.

15) Repeat step 13.

16) Centrifuge for 15 min at 4000 × g. Do not discard the flowthrough; this contains the free N -glycans.

17) Remove the filtrate collection tube, which contains the flowthrough, from the filtration device and place it into a vacuum concentrator to dry for 2-4 h.

18) Transfer the solution from the filtrate collection tube into a 2 mL microfuge tube. Do not discard the filtrate collection tube.

19) Rinse the filtrate collection tube with 200 μL ultrapure water to collect remaining traces of N -glycans and transfer the solution to the microfuge tube. Do this twice.

20) Place the microfuge tube in into a vacuum concentrator and incubate overnight or until completely dry.

5 Labeling and Cleanup

1) Resuspend the N -glycans in 100 μL ultrapure water. If desired, the procedure can be upscaled to a high-throughput format at this point by transferring the resuspended N -glycans to a 96-well plate. The subsequent labeling and cleanup steps can be carried out in 96-well plates.

2) Prepare the 2-AB labeling solution and add 50 μL to each sample. Mix well by pipetting.

3) Seal the plate with an adhesive plate seal and incubate for 10 min at room temperature with gentle shaking.

4) Incubate the plate for 2 h at 65 °C.

5) Remove the plate from the incubator and cool at room temperature for 30 min.

6) Prepare the 1 mL AcroPrep™ GHP membrane 96-well fi lter plate by pipetting 200 μL of 70 % ethanol to each well. Vacuum to waste.

7) Pipette 200 μL of ultrapure water to each well and vacuum to waste.

8) Pipette 200 μL of cold 96 % ACN to each well and vacuum to waste.

9) Prepare the N -glycan samples for cleanup by adding 800 μL of cold 100 % ACN to each sample. Mix well by pipetting and transfer the entire solution to the AcroPrep™ GHP membrane filter plate.

10) Incubate for 2 min.

11) Vacuum to waste.

12) Pipette 200 μL of cold 96 % ACN to each well vacuum to waste.

13) Repeat the previous step three times.

14) Place the AcroPrep™ GHP membrane filter plate on top of a 2 mL stand and pipette 200 μL of cold 96 % ACN to each well of the GHP plate.

15) Centrifuge the GHP plate for 5 min at 165 × g. Make sure the centrifuge is balanced.

16) Place the AcroPrep™ GHP membrane filter plate on top of a 96-well collection plate.

17) Pipette 90 μL of ultrapure water to each well of the GHP plate and incubate the plate for 15 min at room temperature with gentle shaking.

18) Centrifuge the plate for 5 min at 165 × g to collect the first fraction of the eluate into the collection plate.

19) Repeat steps 17 and 18 to collect the second fraction of the eluate.

20) Seal the plate with plastic caps and store at −20 °C.

6 HILIC-UPLC Analysis

1) Prepare sample solution by resuspending 15 μL of fluorescently labeled N -glycans in 35 μL of ACN.

2) Maintain the sample solution at 10 °C before injection and the column at 25 °C during separation.

3) Turn on the lamp of the FLR detector.

4) Equilibrate the system to starting conditions (0.561 mL/min, 27 % solvent A, 73 % solvent B) by gradually increasing the flow rate by 0.1 mL/min from 0.1 mL/min to 0.561 mL/min. Make sure the pressure ripple delta value is ≤ 10 psi before each increase.

5) Inject 40 μL of the prepared solution and run the samples at flow rate of 0.561 mL/min using a linear gradient of 27–29.5 % solvent A in the first 15 min and 29.5–38.7 % for the next 80 min.

Reference

- Lauc, G., & Wuhrer, M. (2017). High-throughput glycomics and glycoproteomics. Springer New York.