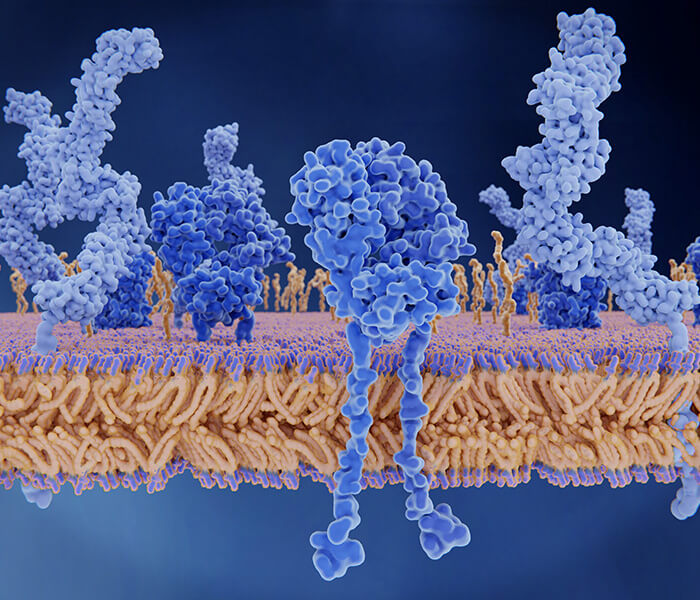

Immunoglobulin G (IgG) stands as the most abundant antibody class circulating in human blood, with a concentration approximately reaching 10 mg/mL. It serves as a pivotal effector molecule in the humoral immune response, playing a crucial role in defending against pathogens and maintaining immune homeostasis. Within the IgG molecule, the Fc region harbors a single covalently attached N-glycan at asparagine 297 within the C H 2 domain of both heavy chains. Additionally, about 20% of human IgG molecules also possess N-glycans within the Fab region.

The N-glycans attached to the Fc region of IgG serve as indispensable structural components, exerting a profound influence on the antibody's effector functions. These functions include complement activation, antibody-dependent cellular cytotoxicity (ADCC), and phagocytosis, among others. Alterations in the glycosylation profile of IgG, termed the IgG N-glycome, have been observed to accompany various physiological parameters, such as age, sex, and pregnancy, as well as numerous pathological conditions, including inflammatory and autoimmune diseases.

Given the biological significance and clinical implications of IgG glycosylation, there has been a growing interest in large-scale studies aimed at comprehensively characterizing the IgG N-glycome. Recently developed high-throughput analytical methods, including liquid chromatography, capillary gel electrophoresis, and mass spectrometry, have facilitated the exploration of IgG glycosylation patterns on a broader scale. These methods offer insights into the structural diversity and heterogeneity of IgG N-glycans, enabling researchers to decipher the intricate relationships between glycosylation and immune function.

Among these methods, mass spectrometric analysis of tryptic IgG glycopeptides stands out for its ability to discriminate between different human IgG subclasses based on peptide differences and provide Fc-specific glycoprofiling. In contrast, analysis of released IgG glycans offers broader glycan coverage but lacks site-specific information regarding glycosylation sites.

To enable high-throughput analysis of the IgG N-glycome, robust and reproducible sample preparation protocols, coupled with accurate quantitative analysis methods, are essential. However, meeting the demands for generating high-quality glycomics data while adhering to time constraints can present significant challenges. Therefore, thorough optimization and validation of protocols are imperative to ensure reliable and efficient analysis.

This study presents a detailed protocol for the optimized and high-throughput analysis of IgG N-glycans using ultra-performance liquid chromatography with fluorescence detection (UPLC-FLR). The protocol encompasses sample denaturation, enzymatic release of N-glycans, fluorescent labeling, cleanup, and subsequent UPLC-FLR analysis. By providing a standardized methodology, this protocol aims to facilitate comprehensive characterization of the IgG N-glycome, advancing our understanding of the role of glycosylation in immune function and disease.

Select Services

Materials

1. 96-well collection plate: Utilized for sample handling and processing, with 1 or 2 mL well volume, providing a high-throughput platform for sample preparation.

2. Sodium dodecyl sulfate (SDS): A detergent used for denaturing proteins, available as either 1.33% or 2% (w/v) solutions, essential for efficient denaturation of IgG samples.

3. Igepal CA-630: A non-ionic detergent crucial for sample preparation, available as a 4% solution, facilitating the removal of contaminants and aiding in the solubilization of proteins.

4. PBS (Phosphate Buffered Saline): A buffer solution used for sample dilution and maintaining pH stability during enzymatic reactions, prepared as 5× concentrated solution at pH 6.6–6.8.

5. PNGase F (Peptide-N-Glycosidase F): An enzyme used for enzymatic release of N-glycans from IgG samples, supplied as a 10 U/μL solution, crucial for glycan liberation from glycoproteins.

6. 2-AB labeling solution: A reagent mixture containing 2-aminobenzamide (2-AB) and 2-picoline borane complex (PB) in 30% acetic acid (HAc) and dimethyl sulfoxide (DMSO), employed for fluorescent labeling of N-glycans, essential for subsequent detection and analysis.

7. Acetonitrile: HPLC grade or higher, used for solvent preparation and sample cleanup, ensuring high-quality chromatographic separation and efficient removal of impurities.

8. AcroPrep™ 0.2 μm GHP membrane 96-well filter plate: Utilized for solid-phase extraction (SPE) cleanup of 2-AB labeled N-glycans, providing efficient removal of excess label and reducing agent, ensuring sample purity prior to analysis.

9. PCR plate: Utilized for collecting eluates during SPE cleanup, providing a convenient format for subsequent sample storage and handling.

10. Reagents for solvent preparation: Including ammonium formate (2 M) for preparing solvent A (100 mM ammonium formate, pH 4.4) and LC-MS grade acetonitrile for solvent B, ensuring optimal conditions for chromatographic separation.

11. Waters Acquity UPLC H-class system: Consisting of a quaternary solvent manager, sample manager, and fluorescence (FLR) detector set with excitation and emission wavelengths of 250 and 428 nm, essential for high-performance liquid chromatography (HPLC) analysis of fluorescently labeled N-glycans.

Methods

Sample Preparation:

- Place the required volumes of 1.33% or 2% SDS, 4% Igepal CA-630, and 5× PBS on the laboratory countertop to equilibrate to room temperature.

- Transfer the IgG samples to a 96-well collection plate, ensuring to use the recommended amount per sample (50–200 μg). Whether dissolved or lyophilized, adjust the total volume of each IgG sample to 10 μL.

- Denature the IgG samples by adding the appropriate volume of SDS solution to each well, depending on the form of the IgG (30 μL of 1.33% SDS for lyophilized samples, or 20 μL of 2% SDS for dissolved samples). Ensure thorough mixing to dissolve lyophilized samples completely.

- Seal the plate with an adhesive seal and incubate at 65 °C for 10 minutes to facilitate denaturation.

- After incubation, allow the plate to cool to room temperature for 30 minutes to ensure proper handling of samples.

- Remove the adhesive seal and add the specified volume of 4% Igepal CA-630 to each well, ensuring thorough mixing by pipetting.

- Place the plate on a plate shaker and gently shake for 15 minutes to ensure proper mixing and solubilization of the samples.

Enzymatic Release of N-glycans:

- Prepare the PNGase F solution by combining the appropriate volume of PNGase F with 5× PBS per sample.

- Add the PNGase F solution to each well containing the denatured IgG samples and mix thoroughly by pipetting.

- Seal the plate with an adhesive seal and incubate overnight at 37 °C to allow for complete enzymatic release of N-glycans.

Fluorescent Labeling and Cleanup:

- Prepare the 2-AB labeling solution as per the specified recipe.

- Following the enzymatic release of N-glycans, add the 2-AB labeling solution to each well containing the samples and mix thoroughly.

- Seal the plate and incubate at the specified temperature for the designated duration to ensure efficient labeling of N-glycans with 2-AB.

- Clean up the labeled N-glycans using HILIC-SPE with a 0.2 μm GHP membrane 96-well filter plate and vacuum manifold. Precondition the filter plate with ethanol, water, and acetonitrile before loading the samples.

- After loading the samples, perform multiple wash steps with acetonitrile to remove excess label and reducing agent.

- Collect the eluate into a PCR plate for subsequent analysis.

UPLC-FLR Analysis

- Ensure the UPLC system is properly set up, including the quaternary solvent manager, sample manager, and FLR detector with excitation and emission wavelengths set to 250 nm and 428 nm, respectively.

- Prepare solvent A (100 mM ammonium formate, pH 4.4) and solvent B (LC-MS grade acetonitrile) as per the specified instructions.

- Prime the solvents for 5 minutes to ensure optimal performance, especially when using freshly prepared solvents or after prolonged system idle time.

- Set the temperature of the sample manager to 10°C and the column temperature to 60°C to maintain chromatographic stability.

- Turn on the lamp of the FLR detector to ensure proper fluorescence detection during analysis.

- Prepare the samples and dextran ladder standard for injection by diluting in 80% LC-MS grade acetonitrile, ensuring the proper amount is loaded for optimal chromatographic separation.

- Equilibrate the UPLC system to starting conditions (0.4 mL/min flow rate, 25% solvent A, 75% solvent B) by gradually increasing the flow rate while monitoring the pressure ripple delta value.

- Run blank (water), dextran ladder standard, and samples using the running method specified in Table 1. Inject the appropriate volumes of each, ensuring to run the dextran ladder standard after every 12–16 samples to monitor system performance and calibrate the runs.

- Calibrate the obtained chromatograms by fitting a fifth-order polynomial distribution curve to the dextran ladder standard peaks. Convert retention times of individual chromatography peaks to glycan units (GU) values using appropriate software for comparison with reference values.

- Quantitate the chromatograms by integrating the peaks using an automatic processing method with subsequent manual verification. Integrate 24 chromatographic peaks for the IgG N-glycan profile, allowing identification of 33 IgG N-glycan structures.

Reference

- Lauc, Gordan, and Manfred Wuhrer. High-throughput glycomics and glycoproteomics. Springer New York, 2017.