What Is TGA for Polysaccharides?

Thermogravimetric analysis measures sample mass versus temperature or time under controlled atmospheres. For polysaccharides, it reveals:

- Moisture states (free vs bound water) at low temperatures.

- Side-group loss and backbone scission at mid temperatures.

- Char formation and inorganic residue at high temperatures.

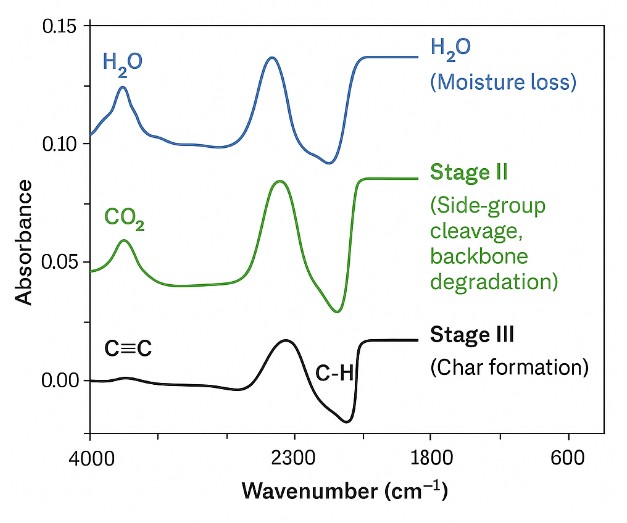

The DTG trace (mass-loss rate) pinpoints event peaks (T_max) and separates overlapping transitions. When paired with DSC, we link mass-loss events to endo/exothermic signals; with FTIR/MS, we identify released species (H2O, CO/CO2, small organics).

At Creative Proteomics, we transform these mass loss curves into actionable thermal fingerprints that guide drying process design, structural characterization, product comparability, and material performance evaluation.

Why Choose This Service

- Linkage to decisions: Clear conclusions for drying, extrusion, baking, sterilization, and storage.

- Dual-atmosphere clarity: Inert (N2/Ar) vs oxidative (air) behavior compared side-by-side.

- Advanced identification: Optional TG-DSC for heat-flow assignment and TGA-FTIR/MS for evolved-gas ID.

- Kinetic modeling (optional): Multi-rate FWO/KAS isoconversional and Kissinger peak methods.

- Transparent quality: Blank and buoyancy corrections, calibration checks, and complete raw files.

When Should You Use TGA for Polysaccharides?

You'll benefit from this service when you need to:

- Establish thermal stability profiles across different sources, batches, or chemical modifications

- Determine moisture content and drying requirements for downstream processing

- Compare thermal performance of native vs. modified polysaccharides (e.g., sulfated, acetylated)

- Quantify residual/ash content for regulatory and functional assessment

- Support quality control, material consistency, or structure–function studies

What Polysaccharide TGA Services Do We Offer?

Core Testing Modes

- Standard TGA (Inert Atmosphere): Thermogravimetric profiling under nitrogen or argon; ideal for baseline thermal decomposition analysis.

- Oxidative TGA (Air Atmosphere): Measures behavior under oxidative conditions; suitable for packaging, food, and excipient applications.

Coupled Thermal Techniques

- TG-DSC (Simultaneous Differential Scanning Calorimetry): Identifies endothermic or exothermic transitions associated with mass loss.

- TGA-FTIR or TGA-MS: Detects and identifies evolved gases (e.g., H2O, CO2, acetic acid) during degradation for mechanistic insights.

Advanced Analytical Modules

- Multi-Rate Thermal Kinetics: Determine activation energy (Ea) using FWO, KAS, or Kissinger methods; supports risk assessment and stability modeling.

- Comparative Overlay Analysis: Analyze differences across batches, treatments, or modifications via superimposed TG/DTG curves.

- Stage-by-Stage Interpretation: Assign mass-loss events to specific structural transitions (e.g., moisture loss, backbone cleavage, char formation).

All modules are available individually or in combination. Not sure what to select? Contact our technical team to discuss the optimal design for your sample type and research goal.

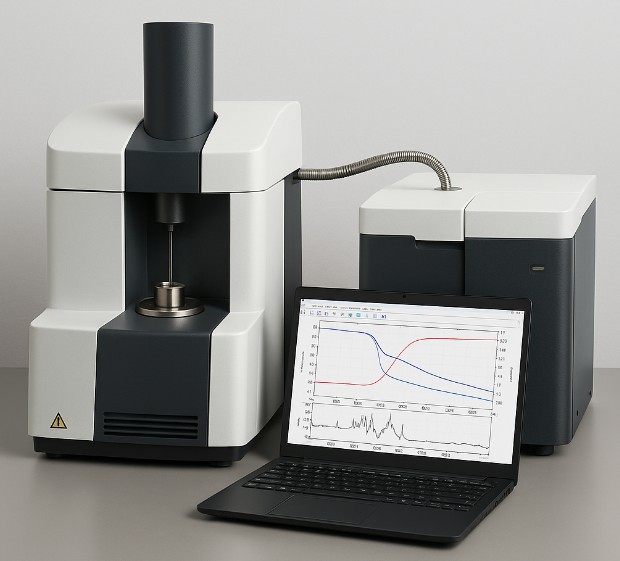

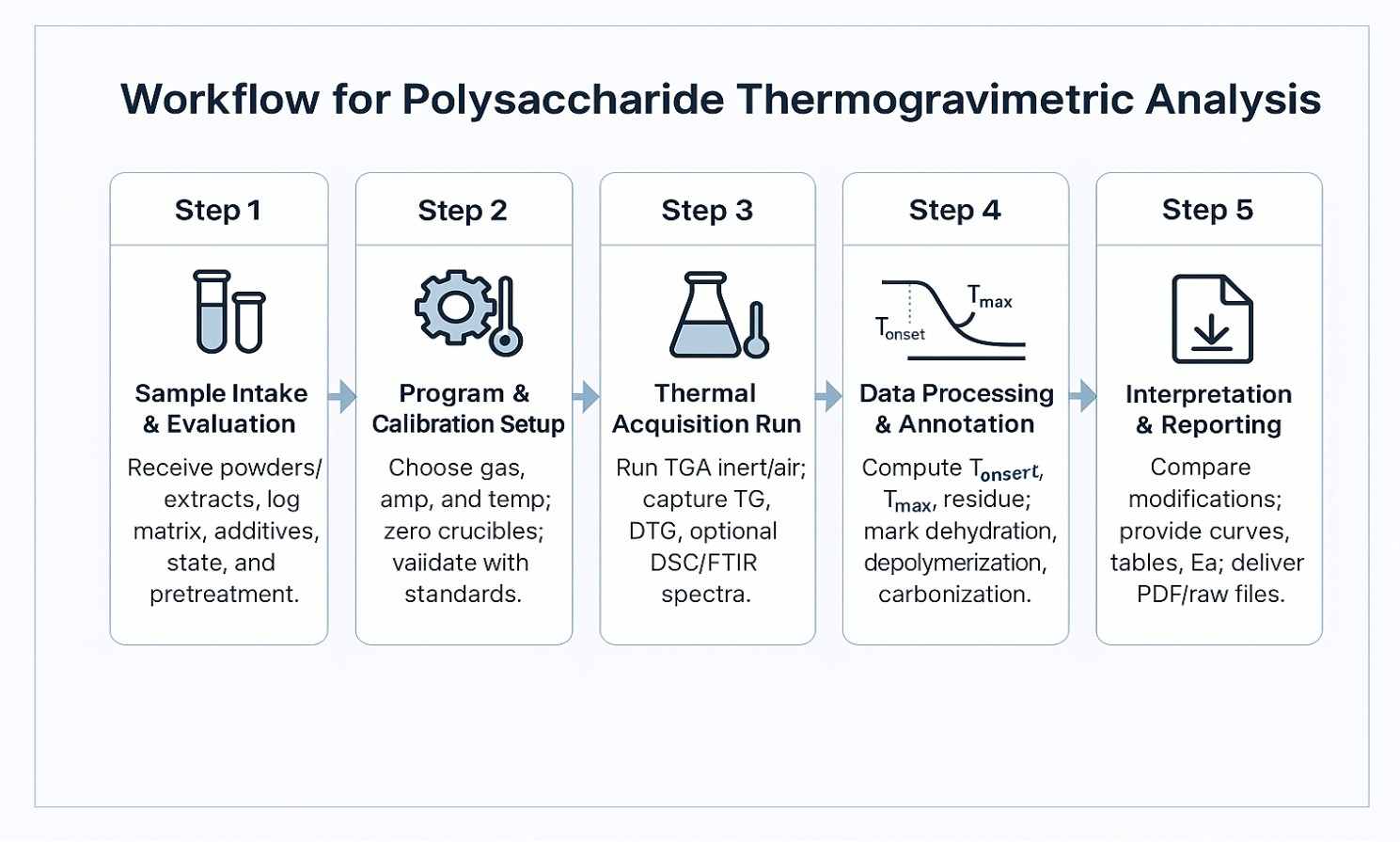

Our Thermogravimetric Analysis Platform

Creative Proteomics operates a high-performance thermogravimetric analysis platform tailored to meet the demands of both standard testing and advanced thermal research. Our instruments are optimized for:

Method Parameters (Typical, Tuned to Your Matrix)

| Parameter | Description |

|---|---|

| Temperature range | 30–800 °C (extendable upon request) |

| Heating rates | 5, 10, 15, or 20 °C/min; multi-rate protocols available for kinetic modeling |

| Atmosphere options | N2/Ar (inert) or synthetic air (oxidative); purge rate: 40–60 mL/min |

| Crucible type | Open or lidded aluminum or platinum pans, based on sample behavior |

| Calibration/QC | Verified with CaC2O4·H2O three-step decomposition; blank/buoyancy corrections applied |

Core Instrument Capabilities

Dual-mode operation: TG-only or simultaneous TG-DSC measurement

Coupled detection: Interface with FTIR or mass spectrometry (TGA-FTIR/MS) for evolved gas analysis

Programmable temperature ramps: Multi-rate protocols for kinetic modeling (FWO, KAS, Kissinger)

Atmosphere control: Rapid switching between inert and oxidative purge

High-resolution balance system: Precise weight change tracking down to microgram level

What Deliverables Will You Receive?

Core Deliverables

- TG and DTG curves with annotated temperature events (T_onset, T_max)

- Overlay comparisons for lot-to-lot or formulation analysis

- Mass loss breakdown (%) per thermal stage under inert and/or oxidative conditions

- Residual/ash content (%): valuable for materials with fillers or inorganic salts

- Interpretive report: connects mass loss patterns to molecular structure, modifications, and process design

Optional Enhancements

- TG-DSC (Simultaneous): reveals endothermic/exothermic transitions linked to mass loss

- TGA-FTIR or MS: identifies evolved gases (e.g., H2O, CO2, acetic acid) to clarify degradation pathways

- Thermal Kinetics (FWO, KAS, Kissinger): estimate activation energies and thermal sensitivity

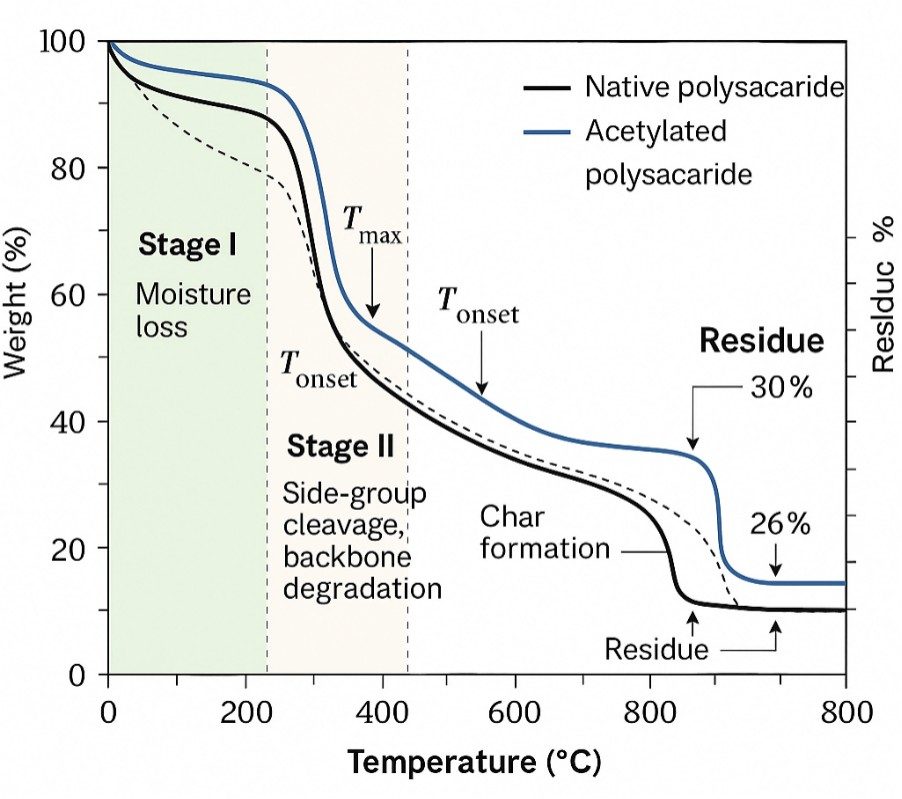

Annotated TG/DTG Curve for Native vs Acetylated Polysaccharides

TGA-FTIR Spectra of Evolved Gases at Key Decomposition Stages

💡 Need help choosing options? Our team will tailor a testing plan to match your sample type, modification level, and application goals.

What Do the TG/DTG Curves Show?

Our reports include fully annotated thermal profiles that decode polysaccharide stability in three primary stages:

| Stage | Temp. Range (°C) | T_onset | T_max | Mass Loss (%) | Typical Interpretation |

|---|---|---|---|---|---|

| I | 30–110 | 65 °C | 80 °C | 5.4 | Moisture loss (free & bound water) |

| II | 200–340 | 230 °C | 298 °C | 51.2 | Side-group cleavage (e.g., acetate, sulfate), backbone scission |

| III | 350–600 | — | 415 °C | 20.1 | Char formation; inorganic residue remains |

For chemically modified polysaccharides, we highlight:

- Shifts in T_max (e.g., acetylation often lowers decomposition onset)

- Changes in residue levels (e.g., sulfation increases ash content)

These stages are visualized in our reports using shaded curve zones, peak markers, and interpretive captions to make insights immediately accessible.

Which TGA Mode Fits Your Application?

We offer multiple TGA configurations to suit different research and industrial needs:

| Configuration | Description |

|---|---|

| TG/DTG (Inert atmosphere) | Baseline decomposition under N2 or Ar – best for material comparison and modification assessment |

| TG/DTG (Oxidative atmosphere) | Simulates real-world exposure to air – essential for food, packaging, and pharma materials |

| Simultaneous TG-DSC | Adds heat-flow context (endo/exo transitions) to mass changes – ideal for phase change mapping |

| TGA-FTIR or TGA-MS | Identifies evolved gases during degradation – suitable for mechanism studies or regulatory dossiers |

| Thermal Kinetics | Multi-rate protocols for calculating activation energy – supports shelf life and thermal compatibility modeling |

Recommendation: For packaging, food, and pharmaceutical applications, we recommend combining inert + oxidative modes

How Should You Prepare and Submit Your Samples?

| Category | Guidelines |

|---|---|

| Sample Quantity |

|

| Aliquoting | Submit separate aliquots if testing under multiple conditions (e.g., inert + oxidative) |

| Physical Form |

|

| Moisture Protection |

|

| Pre-Drying (Optional) | Vacuum dry at ≤ 40 °C to reduce free water and improve accuracy |

| Labeling & Metadata | Provide sample ID, source, preparation method, and any known modifications or additives |

| Known Additives | Disclose salts, plasticizers, fillers, or crosslinkers that may affect residue or oxidation |

Use Cases: Where TGA Data Makes a Difference

![]()

Food & Nutrition

- Define drying or roasting conditions for dietary fibers and gums

- Compare native vs. modified polysaccharides for shelf-life stability

![]()

Biomaterials & Packaging

- Test oxidative resistance of polysaccharide films and coatings

- Benchmark crosslinking or plasticizer effects under heat

![]()

Pharmaceutical Excipients

- Assess decomposition behavior of excipients and carriers

- Verify lot-to-lot consistency and modification impact

![]()

Fermentation & Agriculture

- Characterize microbial exopolysaccharides for process control

- Profile plant-derived polysaccharides for functionality and stability

Frequently Asked Questions

Q1. How do I choose between inert and oxidative runs for my matrix?

Select inert for baseline decomposition and modification effects; add oxidative to simulate real-world exposure and ash attribution.

Q2. What information do you need to design the temperature program?

Matrix/source, prior treatments, expected volatiles, additives/fillers, and decision targets (e.g., drying window, comparability, mechanism).

Q3. Can you run custom ramps or multi-segment programs?

Yes—single or multi-segment ramps, isothermal holds, and multi-rate sequences for kinetics and mechanism separation.

Q4. How is instrument traceability demonstrated?

Temperature and mass verification plus a three-stage CaC2O4·H2O check; blank/buoyancy corrections are documented in the report.

Q5. What files do I receive for independent reanalysis?

PDF report, raw data exports (e.g., mass vs. temperature/time), method files, purge logs, and calibration/QC records.

Q6. How do you separate inorganic ash from carbonized residue?

Compare inert vs. oxidative profiles and quantify residue deltas; optional FTIR/MS helps identify inorganic vs. organic contributions.

Q7. When is TG-DSC necessary?

When endo/exo events must be aligned with mass loss—e.g., deacetylation, crystallization, or oxidation onset assignments.

Q8. What are the practical limits of TGA-FTIR/MS for evolved gases?

Best for abundant volatiles (H2O, CO2, small acids/aldehydes). Semi-quant trends are reliable; trace-level species may require targeted methods.

Q9. How do you ensure lot-to-lot comparability?

Identical programs/atmospheres, replicate runs, overlay plots with aligned T_onset/T_max, and stage-wise statistics.

Q10. Which kinetics model should I request—FWO/KAS or Kissinger?

Use FWO/KAS for conversion-dependent Ea(α) across a range; use Kissinger for peak-based Ea when a dominant DTG event exists.

Q11. Can crosslinkers/plasticizers distort interpretation?

Yes—disclose additives; we adjust pans, purge, and program, and annotate additive-driven shifts in T_max and residue.

Q12. What acceptance criteria do you apply for data quality?

Replicate agreement for event temperatures and stage losses, stable baselines, and verified purge/flow; any deviations are flagged.

Q13. How are moisture states differentiated without over-drying?

We can analyze as-received vs. gently pre-dried aliquots and interpret free vs. bound water from early-stage DTG features.

Q14. Can TGA support regulatory or dossier submissions?

Yes—methods, calibrations, atmospheres, and interpretations are fully documented; we provide traceable raw and processed outputs.